Article available in Chinese, Japanese and Korean:

-

Chinese (Simplified)

Download the document PDF (2.11 MB) -

Chinese (Traditional)

Download the document PDF (2.11 MB) -

Japanese

Download the document PDF (2.07 MB) -

Korean

Download the document PDF (2.02 MB)

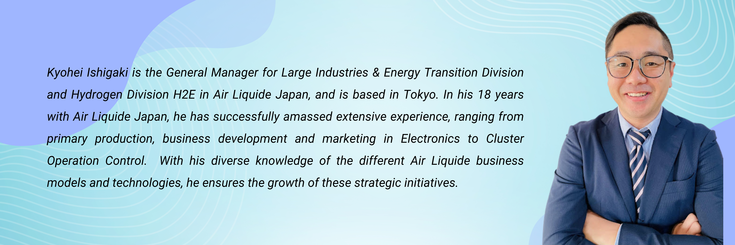

Is a Hydrogen Economy possible or merely a dream? What can we do to truly optimise the potential of Hydrogen? We invite Kyohei Ishigaki from Air Liquide and Masami Takenaka from Asahi Kasei Corp to share their expert opinions.

As a Chemical company with close to a century of operations, what would be the biggest challenges that you face today?

The company was founded in 1922 in Zeze, Shiga Prefecture. Soon later, we acquired the Nobeoka Plant of Nippon Nitrogen Fertilizer in Nobeoka, and began manufacturing ammonia for the first time in Japan in 1923.

The challenge we currently face as a manufacturer is adapting to the circular economy. Traditionally, we operated in a linear economy, importing oil, manufacturing products through processing trade, delivering them to customers, and disposing of them at the customer's site. Japan's rapid economic growth was largely driven by this linear model.

But now, we are making a significant shift towards a recycling-oriented economy, which means that we will no longer need things as we have in the past. This is a major shift that presents a significant challenge but also offers business opportunities. The challenge is to respond to this new reality. Chemistry, with its ability to convert materials using minimal energy, will have a crucial role to play, especially in the reuse of plastics.

How do you view the role of Hydrogen as a key to decarbonisation?

Hydrogen plays a crucial role in decarbonisation, both as a fuel or as a raw material. As a fuel, hydrogen is the ultimate clean energy source, producing only water when burned. It is vital for the shift from fossil fuels to e-fuel (synthetic fuel), in which hydrogen and CO2 are synthesised.

As a raw material, Hydrogen enables the recycling of CO2 into various chemicals, promoting a circular economy. It is essential for carbon recycling, as adding hydrogen to CO2 allows us to get closer to the recycling-oriented society mentioned earlier. Specifically, Hydrogen can be used to synthesise Methane or combined with CO2 to produce Methanol.

I agree. There is no doubt that hydrogen is an essential molecule for a decarbonised society, but it is still unclear how much, when and in which areas it will be needed.

One sector that can certainly leverage the benefits of hydrogen is in the mobility sector, especially for large and heavy-duty trucks where we view Hydrogen as advantageous to electricity. Heavy-duty trucks used for major logistics operations require a long range, high payload capacity, and short refuelling time. Electric vehicles (EVs) carry a large number of batteries, which negatively affects payload capacity. On the other hand, Fuel Cell Vehicles (FCVs) do not require heavy fuel tanks due to the high energy density of hydrogen, so the payload is not sacrificed. FCVs also require a shorter refuelling time than EVs. It is in line with these expectations that we recently opened a hydrogen refuelling station for large trucks in Motomiya, Fukushima Prefecture.

That said, it is clear that the energy transition cannot be achieved by individual companies and requires strategic partnerships. The recent Memorandum of Understanding that Air Liquide Japan had signed with ENEOS is one such example. The partnership will span the whole value chain of low-carbon hydrogen, including the development of low-carbon hydrogen production. We also look forward to kickstarting joint initiatives to develop hydrogen mobility in Japan, through hydrogen refuelling station infrastructure. In the industrial complex, we have been supporting each other and contributing to Japanese industry for many years, even before the energy conversion trend arrived!

That would be my perspective too - I was in charge of a hydrogen project when I was in Germany in 2018. At that time, the only green hydrogen projects were small transportation-related projects. Now, there are global, gigawatt-scale projects being launched. This number has been increasing at an accelerated rate over the past five or six years, and the funding for these projects has grown as well. Considering the scale of the water electrolysis equipment, the volume has become too large for one company to meet the demand.

How are you contributing to the growth of the Hydrogen Economy globally?

In Japan, we have been conducting a 10-megawatt water electrolysis demonstration using Fukushima Hydrogen Energy Research Field (FH2R) in Namie town, Fukushima Prefecture, since it opened in March 2020.

We were the first in Japan to demonstrate 10 megawatts, which produces about 180 kilograms of hydrogen per hour. Since a MIRAI can be charged with about 5 kilograms at one time, it is possible for the electrolysis unit to produce hydrogen for 35 or 36 MIRAIs in one hour. However, 10 megawatts is only one unit.

Hydrogen produced in Namie Town is used in the neighbourhood. It is used for stationary fuel cells at Michinoeki (Roadside) station and J-Village. There is also a hydrogen station in Namie Town, where hydrogen is used.

Our latest Hydrogen station in Motomiya is located close to the Motomiya Interchange of the Tohoku Expressway, where logistic industries are clustered, and is equipped with a dual-lane facility, enabling 24/7 operation. One of the main features of the station is the use of renewable energy-based hydrogen produced at FH2R. The station is a good illustration of the importance of collaborations with many different partners: public and private sectors including Asahi Kasei.

For hydrogen, while there are various types, how do you evaluate the superiority and future potential of each? Low-carbon or zero-carbon? Import or domestic production?

In my opinion, the first priority is to focus on raising awareness on the benefits of hydrogen and getting companies on board to use hydrogen. We cannot move forward if we are obsessed with what we should be doing in 2050.

To do so, we are holding events at hydrogen refuelling stations and even science experiment workshops for children.

I agree. First, it is important to increase the number of places where hydrogen is used, to expand the hydrogen market. The first step is to increase the application of hydrogen, and that is the most important thing. Japan in particular is not blessed with renewable energy, so if we are too focused on only renewable hydrogen, we will fall behind.

The world is moving toward carbon neutrality, so society will change in the direction society desires. So, it is important to introduce hydrogen. Industry-government-academia collaboration is important for this. It is impossible for one company or Japan alone. We need to join hands with a variety of companies and make connections. Overseas partnerships are also important.

In this context, policy support is also necessary. The U.S. IRA (Inflation Control Act) allows up to 2 tons of CO2 to be emitted to produce 1 ton of hydrogen. We need to think about how to run through the transition zone, rather than suddenly aiming for the goal of capturing it all, so that we can pass it on to the next generation. We are seeking a realistic solution while reaching for an ideal.

What technological innovations are you working on in the field of hydrogen? What about CCUS technology?

Air Liquide is working on hydrogen-related technologies, taking advantage of its 60 years of experience in the production and delivery of the molecule. Hydrogen is not easy to handle for storage and long distance transportation in its gaseous state. It can be transported more efficiently in the form of liquid hydrogen or hydrogen compounds, so-called hydrogen carriers.

In Japan, LH2 (Liquid hydrogen), NH3 (ammonia), and MCH (Methylcyclohexane) are currently being considered as hydrogen carrier options, and it is expected that most of not all of these carriers will be mixed in the future. As part of the development, Air Liquide is building a pilot plant in Belgium that uses ammonia cracking to produce hydrogen in a way that optimises its carbon footprint. The above is just one example, and the Group will continue to develop various technologies and bring them to the market, thereby contributing to a low-carbon society. At the same time, as one of the infrastructure companies, we would like to put our maximum effort into market activation to increase the demand for hydrogen.

Although still in the process of R&D, we are working on CO2 capture technology at Mizushima. Zeolite, development to selectively capture CO2. Next fiscal year, a demonstration will be conducted at a sewage treatment plant in Mizushima (Kojima). Kurashiki City generates electricity with biogas. It will be made into high purity methane, and the CO2 from biogas will not be counted, so it will be counted as carbon negative, which will be a value. Fixation is the key point.

They have been producing polycarbonate using CO2 since 2001. We are trying to expand the use of this technology to other resins. It will take time to commercialise this technology, but in the future we would like to create green chemistry by combining the cycle of capturing CO2 and using it as a raw material with green hydrogen.